Summarize

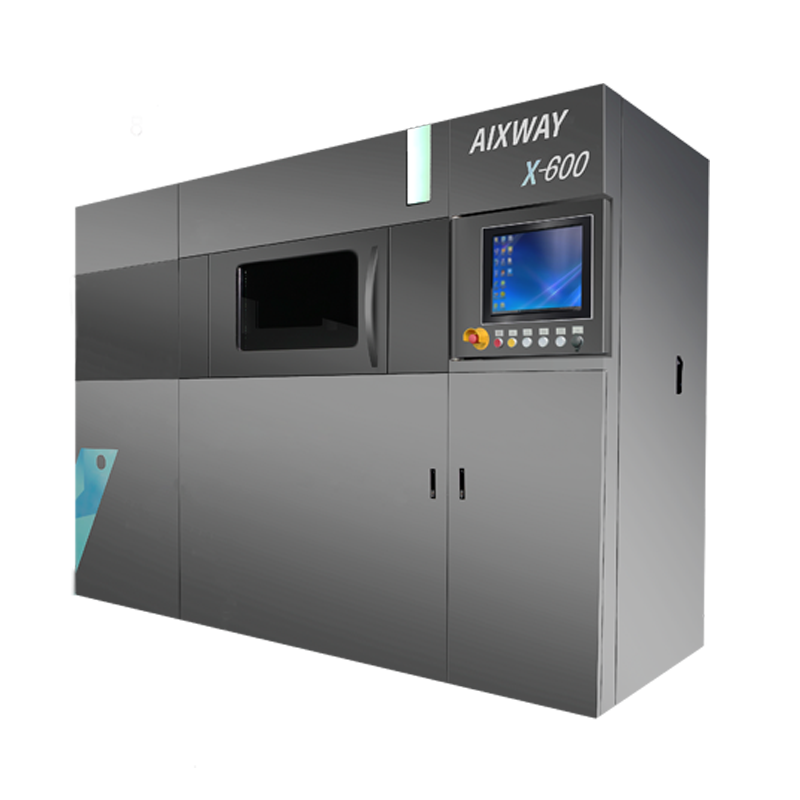

3D printing technology has a high degree of manufacturing flexibility, which is particularly suitable for use in personalized mass manufacturing medical scenarios. Modeled directly from CT scan data, Through the method of additive manufacturing, joint structures such as prostheses that are suitable for the unique characteristics of patients can be quickly manufactured, which can achieve a high degree of matching with the patient's damaged parts, improve the accuracy of medical products and the success rate of surgery, and greatly save the treatment time and cost. In addition, the development of micron-scale metal printing technology also provides support for the development of micro-complex structure interventional medical devices, greatly optimizing the structure of interventional devices, taking into account the performance of micro-complex structure interventional devices.

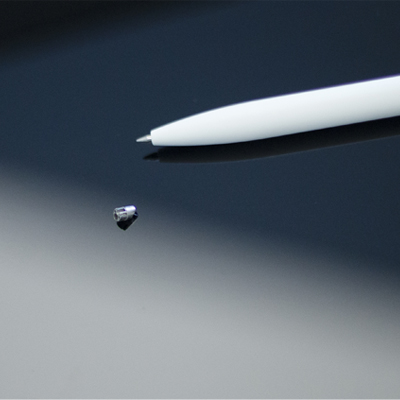

Medical sample

Fine complex medical structure, the smallest aperture is 80 microns, the thinest wall thickness of 30 microns, while reducing the size of the product, to ensure the structural strength of the product.

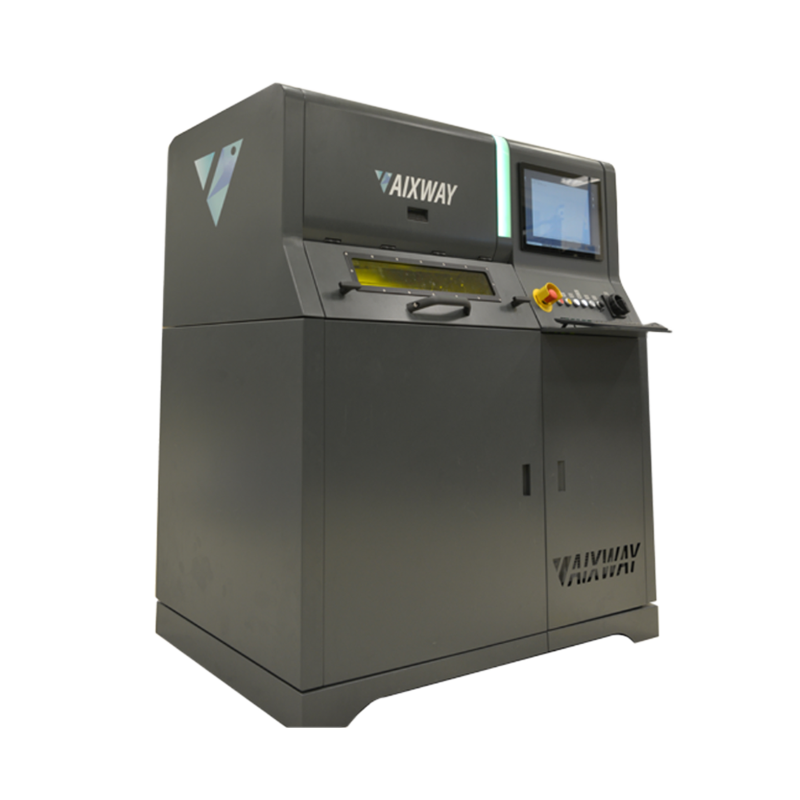

Medical sample

The sample has the characteristics of beautiful appearance and short correction cycle, and the manufacturing cycle is greatly reduced and the manufacturing precision is improved by the direct printing of micro-metal 3D printing.