Conventional metal 3D printing

LPBF/SLM

Technology

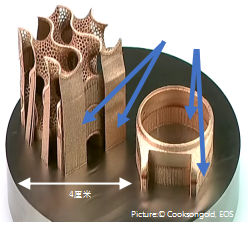

Metal printing mainstream technology, forming density close to 100%, superior mechanical properties of partsLaser powder Bed Fusion technology LPBF, also known as laser selective melting technology SLM, is used in more than 80% of metal 3D printing technology. Through the direct thermal action of the laser on the metal powder, so that it is completely melted and then quickly cooled and formed, you can directly obtain several Almost any shape, with a complete metallurgical combination, density up to 99.999%, mechanical properties of the metal parts, printed parts in various fields of industry is widely used.

Products and Services

Yunyao Shenwei expert team has in-depth cooperation with the world's leading enterprises in the field of advanced manufacturing, and has rich experience in equipment manufacturing and process research and development. Automobile manufacturing, mold manufacturing and other fields to provide conventional size, large size metal parts of the product printing, technology development, scientific research cooperation and other services, At the same time, we provide customers with standard equipment, custom equipment design, research and development and manufacturing services to meet the special requirements of the industry.

Printable Material

Deep research and development, overcome a variety of materialsPrintable materials include pure copper, aluminum alloy, magnesium alloy, pure tungsten, Ni-Ti memory alloy, cobalt-chromium alloy, Ni-base alloy, Ti-base alloy, iron-based alloy, Stainless steel, die steel, precious metals, etc.

Micron scale metal 3D printing

MICRO LPBF/SLM

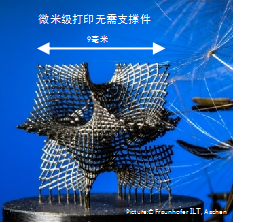

In order to solve the pain points of metal 3D printing process in the field of high-precision structural parts, in addition to conventional size metal additive manufacturing, The exclusive micron metal 3D printing technology independently developed by the company realizes the 3D of complex and precise structural metal materials Printing molding, can achieve printing accuracy ≥2 microns, printing parts surface roughness Ra value ≥0.8 microns, to achieve 10 degrees Most of these components are formed without support, aiming to fill the market gap for high-precision additive manufacturing components.

Conventional metal printing versus micron printing

| Conventional printing | Micron printing | |

|

Precision appeal |

Accuracy 50-200 microns |

Accuracy:2-10 microns |

|

Apparent appeal |

Ra value 7-20 microns | Ra:0.8-2.8 microns |

| Support demand |

Less than 45° most structures need to be supported |

A variety of structures above 10° are formed without support |

|

Precision comparison |

Conventional printing mainly has the following problems: -Typical layer thickness:30-100 microns -Powder size:15-53 microns -Molding accuracy:50-200 microns Precision cannot meet the requirements of precision components |

Micron metal 3D printed parts: -Molding accuracy:2-10 microns -Typical layer thickness is 5 microns Precision to meet the needs of precision structure |

|

Surface contrast |

Conventional metal 3D printing surface roughness is poor: -Ra is about 7-20 microns -Typical surface roughness Ra6-20 microns -Maximum height of profile Rz40-100 microns Require a lot of post-processing |

Micron printing surface roughness: -Ra: 0.8-2.8 microns -Maximum height Rz≥5 microns -Sa≥1.6 microns Various structures require no post-processing |

|

Support correlation |

Conventional printing surface less than 45° need to add support structure auxiliary molding, after the molding needs a lot of manual work to remove the support, resulting in time, material, cost waste at the same time will have a greater impact on the roughness and accuracy of the support surface. |

Micron-level 3D printing can achieve unsupported one-step molding due to its special optical path design and precise control of the process, and can achieve unsupported molding of a variety of structures above 10°. |

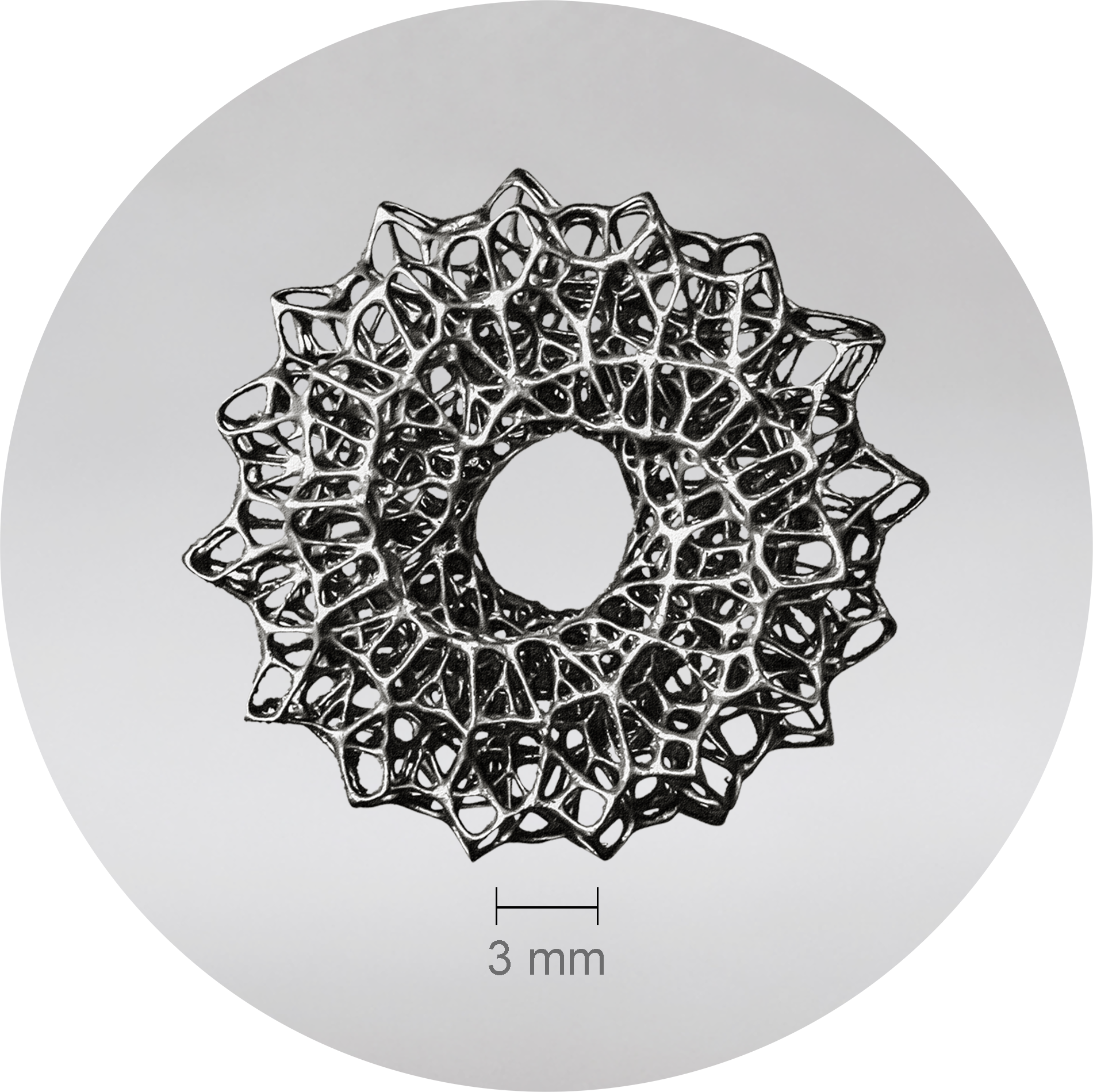

Micrometer scale metal 3D printing typical structure

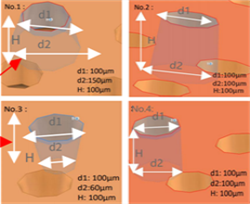

Surface roughness comparison diagram

Material: nickel-titanium alloy

Component: Heart stent

Conventional printing

Conventional printing

Direct print surface comparison

Micron printing

Micron printing

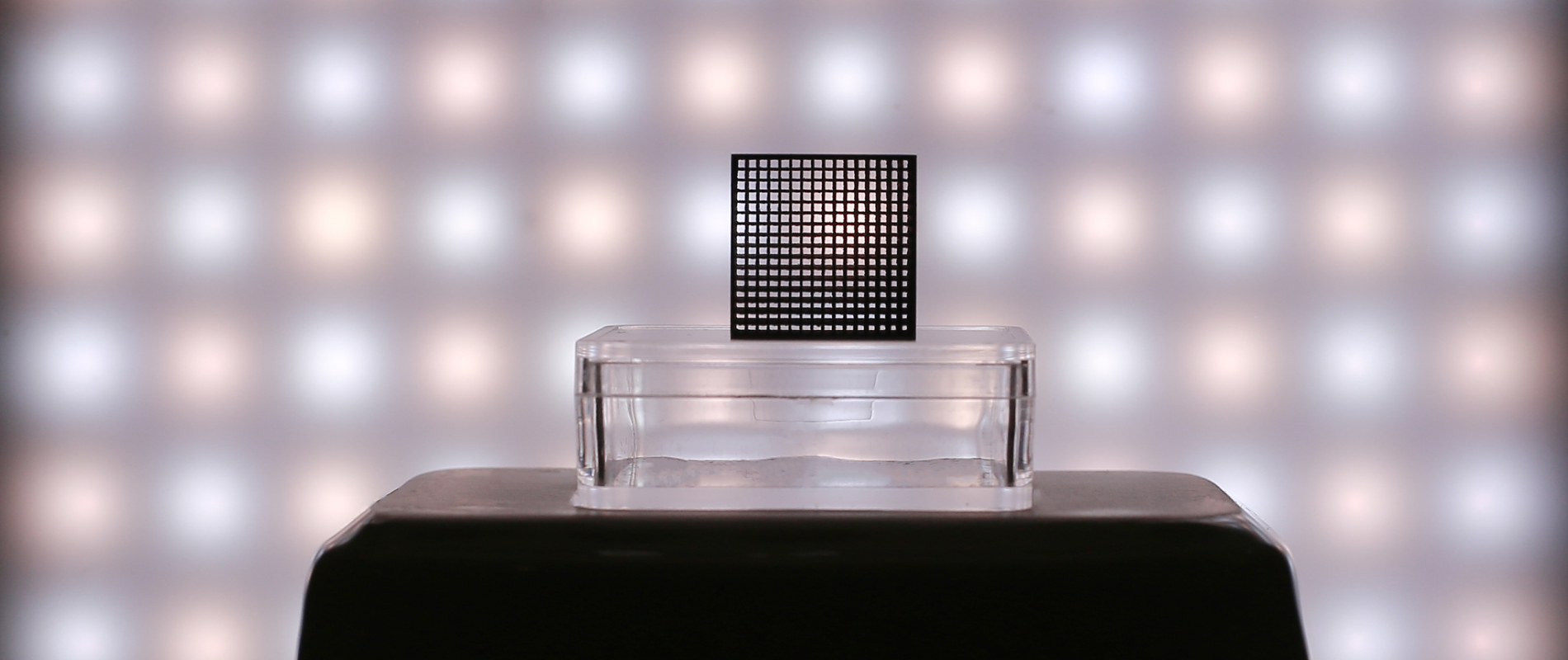

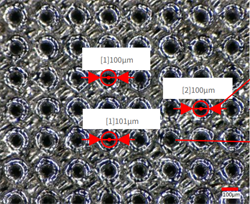

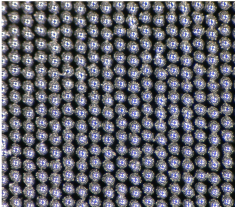

Micrograph of porous structure

Material: 316L

Parts: 100 micron deep hole structure

Tolerance: ±1 micron

Special structure: It can realize the structure of opposite hole

Support comparison chart

Conventional printing overhangs require a large number of support structures, which need to be manually removed in the later stage

Micron printing enables unsupported molding of large twisted overhangs

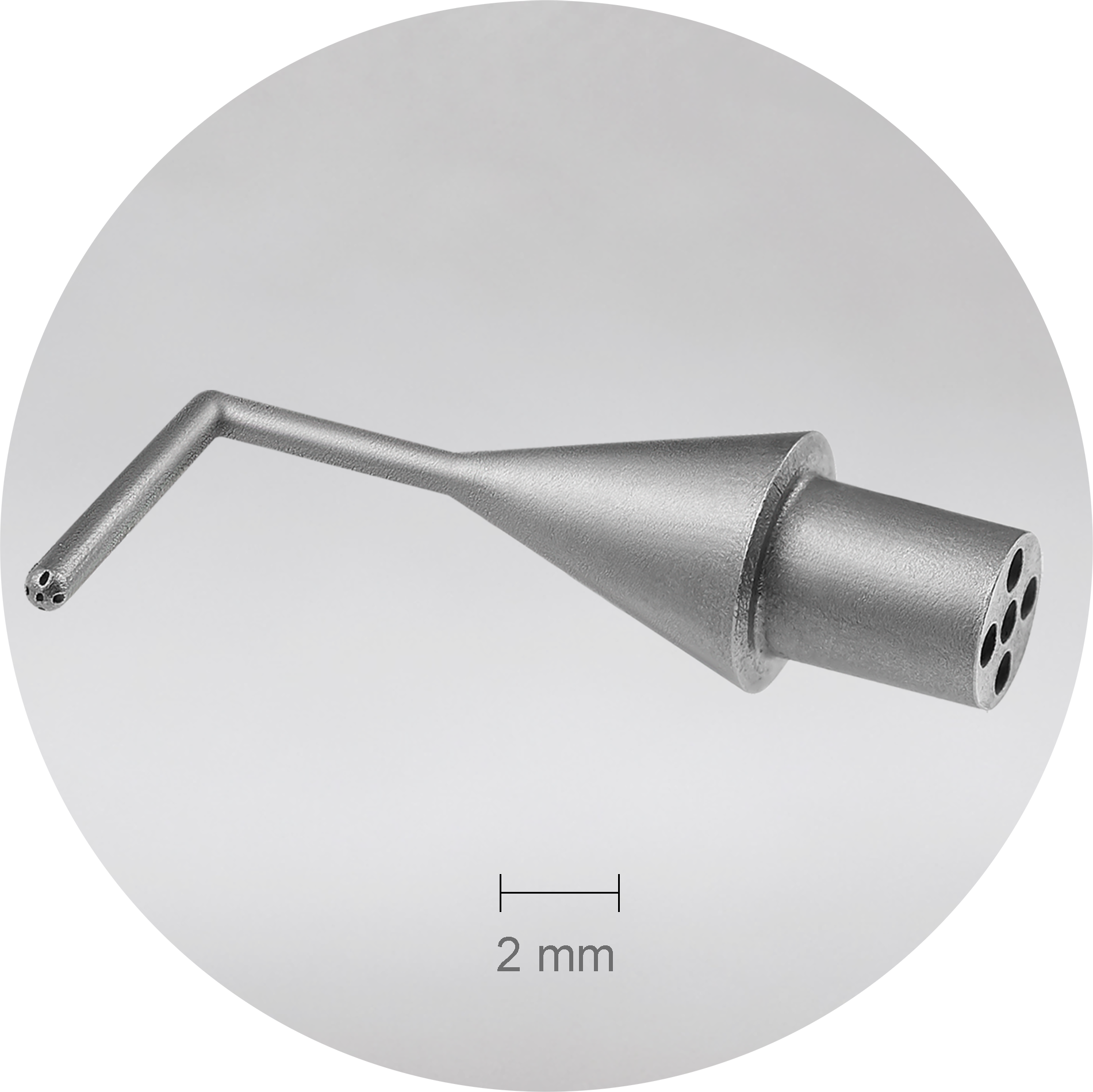

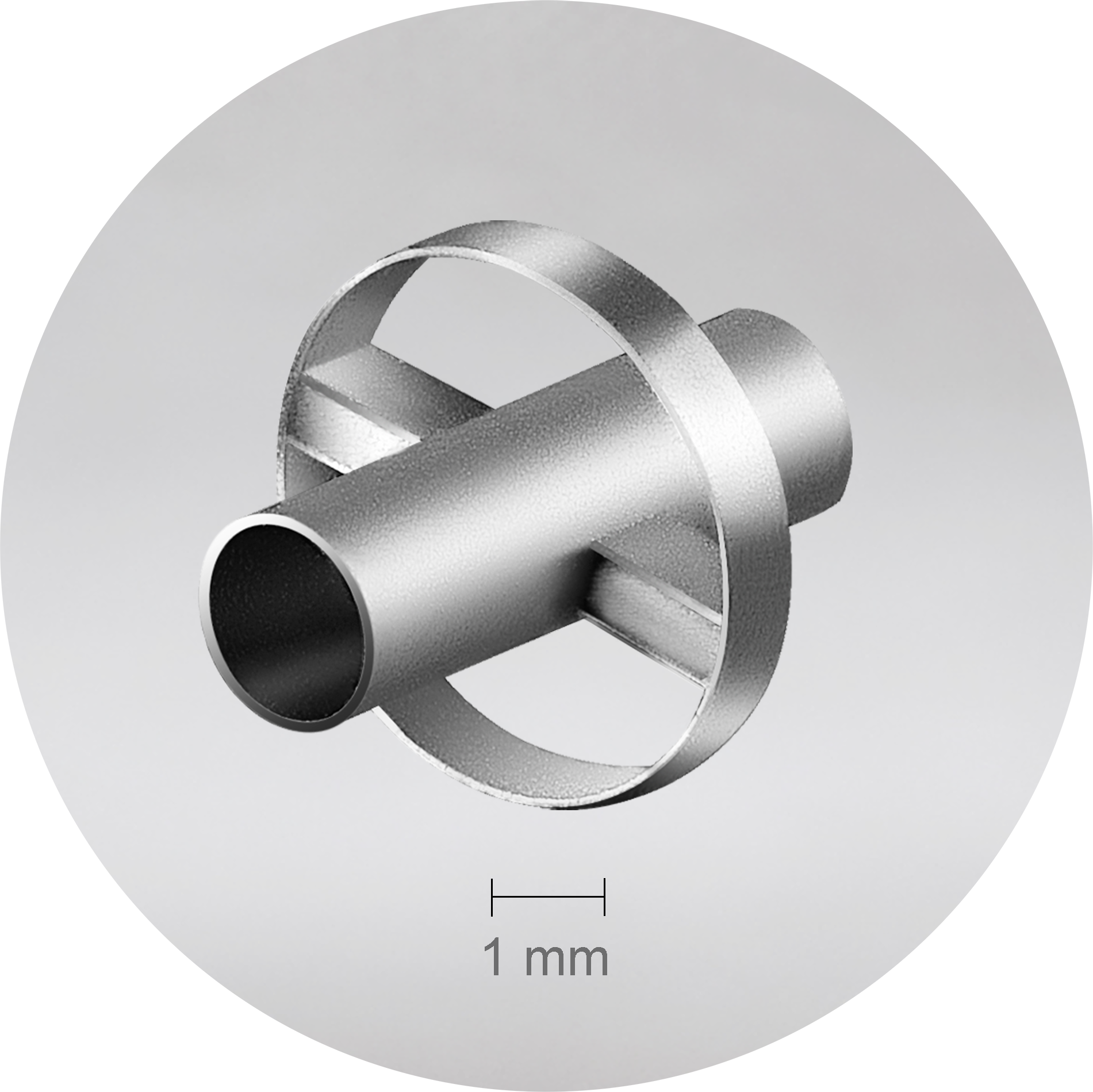

Microstructure of thin-wall structure

Material: 316L

Special structure: ultra-fine cylindrical hollow structure

Components: 30 micron thin-wall structure

Special structure: can achieve curved thin wall structure